Design for Manufacturability and Assembly (DFM/DFA)

Design for Manufacturability and Assembly (DFM/DFA)

Everyone Can Improve Thier Product Design and Development Skills

No matter your role in the organization, it’s important to consider the downstream impacts of your efforts as a product designer, manufacturing, assembly or service professional. With this program and digital workshop you’ll experience the fundamentals of Design for Manufacturability and Assembly (DFM/DFA). With practice and application of these skills, you’ll be able to optimize ideas and improve products, processes, and services.

In this program, you will learn the foundations of design for sample fundamental DFM/DFA methods and tools to gain an understanding of what might work best for your organization.

This session has been updated to include key learnings from out most recent real world client case stories. Sharing successes, key learnings, and being real in the amount of energy and effort required to optimize design and manufacturability in today’s organization.

The case stories demonstrate how application of the methods and approaches have helped their organizations put energy into uncertainty, improve resiliency, build internal capability and, most importantly, deliver results for long term growth.

Within the certification period, you will work 1:1 with an Innovation & Growth Master Black Belt from The Innovation Garage and apply your learnings to 2 DFM/DFA application assignments for your organization.

Following successful completion of the application assignments within the designated certification period, you will be awarded a DFM/DFA Certification.

In this workshop you’ll learn the very basics on:

- An Introduction to DFM/DFA Methods and Approaches

- Minimum Component Strategies

- Mistake Proofing Concepts

- Material Selection Basics

- Introductions to Tolerances

- Basic Jig and Fixture Components

- Cost Estimation

- Ergonomics and Hand Clearances

- Component Manufacturing Process Selection (MPS)

- Design for Assembly (DFA) Practices and Analysis

- How lean relates to DFM/DFA

- A series of standard worksheets and templates to enable more effective product designs

HOW IT WORKS

1) Convenient On-Line Digital Classes & Survey’s: Before attending the session, you take a short strengths assessment, and watch a few short videos. Plan on four (4) hours of virtual pre-work prior to the session for your assessments, and to watch skills videos and complete quizzes.

2) Practical “Hands on” Class: At the live remote class you’ll roll your sleeves up in interactive experiences to cover the content in a dynamic, fast paced way. The course content is covered in three two-hour sessions over three consecutive days.

3) Valuable Application to Your Work: By attending the program, you’ll get started applying the new mindset, systems, and tools to your work – connecting the dots from theory into practical application.

DFM/DFA Certification: Extend your education, and increase your confidence with expert coaching and receive an Design for Manufacturability/Design for Assembly Certification.

Over the Twenty One (21) day coaching and certification period following the live digital sessions, apply your learnings to two (2) application assignments for your organization.

Following successful completion of the two (2) application assignments, within the specified certification period, you will be awarded a Manufacturability/Design for Assembly Certification from The Innovation Garage.

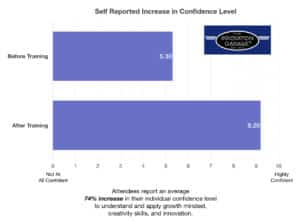

PROOF IT WORKS

WHAT ATTENDEES SAY

“Intense. Insightful. A wake up call for me.”

VP – Global Fortune 500 Financial Services Company

“Really enjoyed the practical application and hands on learning, the group collaboration for different points of view, and pushing my limits to think differently.”

Innovation Analyst, Fortune 200 Company

“Great details with very good content and road map on what to do.”

Supply Chain Leader, Privately Held CPG Company

“This is a hands-on program, providing a great explanation on how all the innovation techniques work together.”

Operational Excellence Facilitator – Hospital Network

“Good Balance on Theory and Practice”

Supply Chain Leader – Publicly Traded Pharma Company

“Going into this training, I had always felt like I had nothing to contribute to the creative process responsible for forming new ideas or products. I had thought that this was fine, and what I lacked in creativity I made up for in my strong ability to execute and I should just follow what my strengths were. What this training made me realize was that anyone can be creative and contribute valuable ideas but more importantly, it provided the skills necessary to develop ideas AND reinforced those skills through application assignments. I think the last part of that sentence was the most important part for me, I find that myself, like most people, learn most effectively when skills are used and applied. This process taught me that I could be creative and still execute and that I could directly influence others to do the same.”

Innovation Process Leader – Global Food Science Company

“A Great Hands on Experience and networking opportunity with other organizations!”

Innovation Analyst, Fortune 200 Company

“This program is an asset to my growth and I look forward to continuing to use what I have learned!”

Research Scientist – Global Food Science Company

“One of my favorite things about the course and content is the ways it challenges you to think – but that in that it removes all barriers. You have to think about how you would bring this to market if there weren’t any limitations. That kind of thinking is freeing and helps you get excited about the opportunity. I feel like every time I have applied the training I have found myself thinking “this will really work – it is a good business idea.”

Innovation Research Leader – Global Food Science Company

“I really enjoyed the smaller class size, learning the methods, then applying what we learned right away.”

Project Manager – Mid-Market Privately Held Technology Company

-

Design for Manufacturability and Assembly

June 13, 2023 - June 15, 2023

9:00 am - 12:00 pm

Venue: Online Digital Workshop

Venue Phone: 3304158888

Description:

Registered participants will receive a link and invitation to the digital classroom following confirmation of registration.